According to the requirements of the thermal spray industry, TPS Solutions GmbH develops, in close cooperation with the customers, tailor-made solutions for spray systems and facilities, based on the latest technologies.

Solutions for spraying systems and equipment, based on the latest technologies.

Worldwide support, wherever you are. • TPS Solutions offer a wide range of spare parts for all common spraying systems. • Spray guns, electrodes, nozzles, barrels, powder injectors, powder conveyor consumables, cables, and hoses.

Worldwide support wherever you are.

Laboratory Services • Sampling • Sample Preparation • Hardness Testing • Surface Roughness Measurements • Microstructure Analyses • 3D Surface Analyses

From sample collection to reporting.

Atmospheric plasma coating or plasma spraying is one of the thermal coating processes and is ideal for metallic and ceramic materials. For this purpose, a high-speed plasma stream is generated, which reaches temperatures of up to 20,000°C. This enables ceramic as well as metallic materials to be melted and coated. At the outlet of the plasma nozzle, the coating powder is fed in by means of injectors. On the way to the workpiece, the powder particles are accelerated and simultaneously heated so that they hit the surface of the component with high temperature and high kinetic energy. As a result, a corrosion- and/or wear-resistant layer is formed on the surface.

The TPS PSS1000 plasma systems feature the latest automation technology from Siemens TIA Portal or Mitsubishi GX Works. The simple, user-friendly operator interface and programme sequences evoke a high level of acceptance among the operating personnel right from the first commissioning. The systems are built according to the latest safety standards. Continuous parameter monitoring and control with high-precision sensors and controllers ensure excellent quality control of your coating process. The Advanced Remote Interface also enables extensive data communication between the plasma system and the robot or other handling systems. Each TPS plasma system is designed according to customer requirements. For example, with a data acquisition system for all relevant spray and process parameters. The data acquisition (datalogger) system stores the data for an entire process time for a specific component. This protects the components from errors during coating.

Our Core Systems are available in two designs: PSS1000 APS Core System - GMC out and for smaller space PSS1000 APS Core System - GMC in.

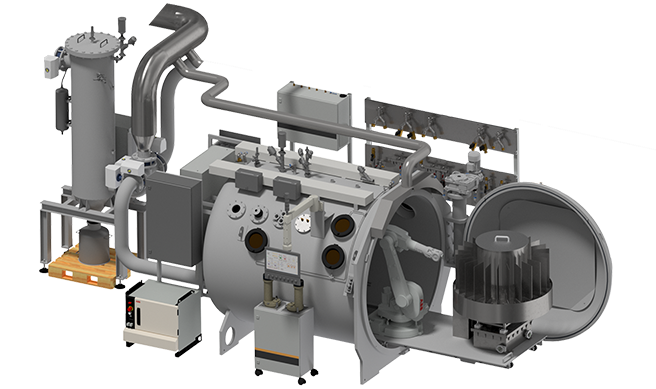

In vacuum plasma spraying (VPS), a high-speed plasma jet is generated in the same way as in atmospheric plasma spraying (APS). However, compared to the APS process, the coating process takes place under low-pressure conditions, in a specially designed vacuum chamber. A pump system evacuates the chamber to achieve the desired vacuum level. VPS technology thus enables more precise process control and extended facility utilisation. • Control of particle heating and particle velocity • Processing of reactive coating powders (e.g. titanium, iron alloys, silicon).

Areas of application

Almost all coating materials can be processed using vacuum plasma spraying. In addition, the VPS process allows coatings to be applied over a wide pressure range, which is directly reflected in the coating properties (lower coating porosity).

The TPS VSS1000 plasma systems feature the latest automation technology from Siemens TIA Portal or Mitsubishi GX Works. The simple, user-friendly operator interface and programme sequences evoke a high level of acceptance among the operating personnel right from the first commissioning. The systems are built according to the latest safety standards. Continuous parameter monitoring and control with high-precision sensors and controllers ensure excellent quality control of your coatings. The Advanced Remote Interface also enables extensive data communication between the plasma system and the robot or other handling systems. The VPS vacuum plasma spraying system is modular and available in various configurations, from an R&D system to a high-production vacuum coating system with multi-spindle workpiece handling.

In high velocity flame spraying, continuous fuel combustion takes place under high pressure within a water-cooled combustion chamber. The fuels used are "gas fuel" (such as propane, ethylene, propylene, butane, acetylene, hydrogen), "liquid fuel" (e.g. paraffin / isopar) and also combinations of these. The high pressure of the burning fuel-oxygen mixture generated in the combustion chamber and the expansion nozzle create the necessary high velocity of the gas jet.

The spray materials, which are usually in powder form, are fed either axially in the combustion chamber or radially in the area of the nozzle. On their way to the workpiece, the powder particles are accelerated and simultaneously heated so that they hit the surface of the component at high temperature and speed.

The TPS PSS1000 HVOF-GF / -LF* systems feature the latest automation technology from Siemens TIA Portal or Mitsubishi GX Works. The simple, user-friendly operator interface and program sequences elicit a high level of acceptance from the operating personnel right from the first commissioning. The systems are built according to the latest safety standards. Continuous parameter monitoring and control with high-precision sensors and controllers ensure excellent quality control of your coatings. The Advanced Remote interface also enables extensive data communication between the HVOF system and the robot or other handling systems. The HVOF spray system is modular and available in various configurations.

*Depending on the system configuration

GF = gas fuel

LF = liquid fuel

TPS Solution's coating systems have been developed using the latest technology. Together with the specially developed software from TPS Solution, this allows you to combine your coating system as you wish. Subsequent extensions can also be realised with simple means. An example: You have an APS system from TPS Solution. Since the order situation has changed, you would also like to spray with an HVOF system on this coating system so that you have maximum system utilisation.

You can make this possible in just a few steps:

1. send an enquiry to TPS Solution.

2. the company TPS Solution will manufacture your required additional modules.

3. TPS Solution will integrate the modules into your system in a few simple steps.

With our design, engineering, and production experience, we offer complete turnkey solutions, including manufacturing drawings, and support you in developing successful concepts for the implementation of innovative ideas. Based on our broad experience of the coating process, we show you potential for improvement in the field of coating, material selection, manufacturing process, operating and maintenance instructions.

TPS turnkey solutions offer you advantages in many respects:

• Complete service package from a single source, from planning to execution

• High functional, system and maintenance reliability through the use of modular, field-tested assemblies

• One contact for the entire system including peripheral equipment

• Uniform automation concept

• Extensive tests before delivery at the factory (FAT = Factory Acceptance Test)

• Shortened commissioning on-site

• Competent on-site service by a service partner.

TPS provides the following support for robotics, i.e. torch handling and workpiece handling:

• Robots for plasma torch guidance

• Robots for workpiece handling (loading and unloading)

• Robot modification for vacuum operation

• Commissioning robots

• Assistance with robot programming

The TPS Twin-10 "stand-alone" metering unit is an independent module that dispenses spray powder in a controlled manner. The powder feed unit essentially consists of the following components:

• Powder funnel with integrated metering unit, available in different sizes 1.1, 1.5, 3.0 and 5.0 litres

• Cabinet with Siemens PLC and control panel, switchable between manual on-site operation or remote mode.

Features of the Twin-10 stand-alone model

• High-precision carrier gas control using digital mass flow controllers

• Integrated memory for up to 150 recipes

• Carrier gas switching (N2 or Ar)

flow rate, stirrer speed, dosing disk speed)

Optional extensions

• Heating mantle with temperature controller for powder hopper

• Weighing system (gravimetric dosing / type "FRC")

• Filling aids for dust-free filling

• Other special wishes and options on request

As an innovative company, we offer you technical systems that do not yet exist on the market or that are not tailored to your requirements and conditions. For this purpose, TPS develops and implements customised solutions that are already established at numerous companies in a wide range of industries.

When developing new systems, we work closely with our customers:

You know your objectives and what you want to achieve. From this, we derive the specific task, develop the solution approach, and implement it accordingly.

Advantages:

Tailor-made solution

Highest degree of flexibility

Industry-experienced contact persons

TPS and its innovative solutions guarantee the success of your projects, from the concept phase to commissioning.

According to the requirements of the thermal spray industry, TPS Solutions GmbH develops in close cooperation with the customers, tailor-made solutions for spray systems and facilities, based on the latest technologies. Our special know-how in system design and the construction experience for thermal spray equipment allow us to offer our customers optimised solutions. We develop complete systems with you, including manufacturing drawings, and support you in developing new concepts or integrating new innovative ideas. Based on our broad and longstanding experience, we show you potential for improvement in the field of coating, material selection, manufacturing process, operating and maintenance instructions.

• Development and production of new systems

• Modernisation and expansion of existing systems

• Major overhaul of existing systems

• Development of coating solutions

• Coating analyses in the in-house laboratory

You have an idea, but you are not sure whether it is feasible, or you would like to put your latest development to the test? For this purpose, we offer you our specially developed test facility for rent. A wide range of torches as well as a multi-axis handling system (robot with turntable) complete our offer. With our pilot facility, you can carry out realistic tests and at the same time obtain reliable values to validly scale your "large-scale facility". If you wish, we can accompany you throughout the entire test period and are at your side every step of the way with our longstanding experience.

Furthermore, our fully equipped test laboratory offers you the possibility to examine your spray tests in detail.

• Hardness testing

• Surface roughness measurement

• Microstructure analyses

• 3D surface analyses

To assess the microstructure, the sample must be prepared and analysed according to the rules of metallography. This preparation is a "science" in itself and requires great experience and careful selection of the consumables used.

Our experts at TPS support you with inspection activities in the area of:

• Sample preparation

• Sampling

• Hardness testing

• Surface roughness measurements

• Microstructure analyses

• 3D surface analyses.